Materials

Q1. An aerospace engineer has built two differently designed wings. One wing is made from an aluminium alloy and the other is made from a carbon fibre composite. The engineer tests a sample of each material by applying a varying stress.

(a) Tick two of the boxes in the table below to indicate which are properties of the material from which a wing is made.

| breaking stress |

|

| stiffness constant, k |

|

| tensile strain |

|

| tensile stress |

|

| Young modulus |

|

[1 mark]

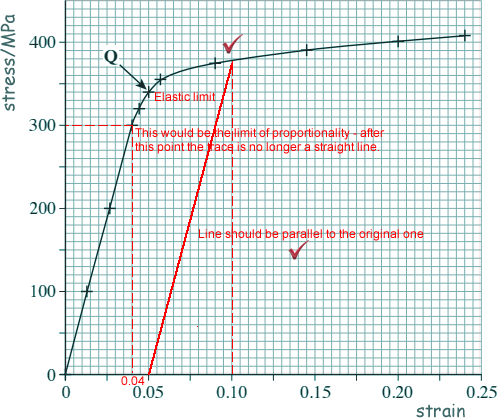

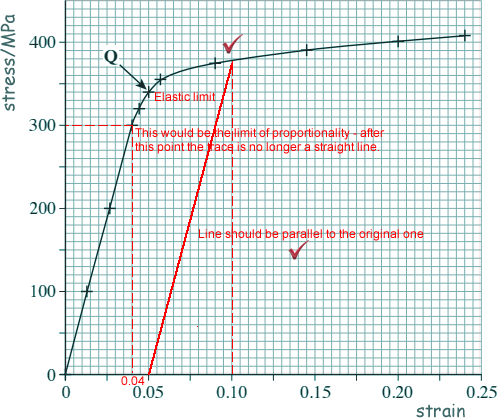

(b) The graphic below shows the stress–strain graph that the engineer obtains for the aluminium alloy:

(i) The engineer has labelled a point Q on the graph. This is a point beyond which the behaviour of the material changes irreversibly.

State the name for this point.

Elastic limit

[1 mark]

(ii) Use the graph to determine the Young modulus of the aluminium alloy.

Show your working.

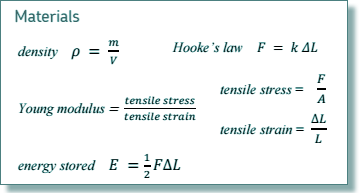

Young Modulus = 300 x 106/0.04 = 7.5  x 109

x 109  Pa

Pa

[2 marks]

(c) The engineer who carried out the experiment to obtain the stress–strain graph decided to stretch another sample to a strain of 0.10. She then gradually reduced the stress to zero.

Show by drawing on the graph above how you would expect the stress to vary with strain as the stress is reduced.

[2 marks]

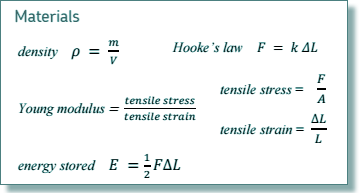

(d) Calculate the volume of 25.0 kg of the aluminium alloy.

density of aluminium alloy = 2.78 × 103 kg m–3

ρ = m/v

so v = m/ρ

vAlloy = 25.0/(2.78 × 103)

vAlloy = 8.99 x 10-3 m3

[1 mark]

(e) 1.28% of the aluminium alloy's volume is copper.

Calculate the mass of pure aluminium needed to make 25.0 kg of the aluminium alloy.

density of pure aluminium = 2.70 × 103 kg m–3

100% - 1.28% = 98.72% of the 8.99 x 10-3 m3 is aluminium

vAl =0. 9872 x 8.99 x 10-3 m3

ρ = m/v

so m = vρ

m = 0. 9872 x 8.99 x 10-3 x

2.70 × 103

m = 23.96 kg

m = 24.0 kg

[2 marks]

(Total 9 marks)