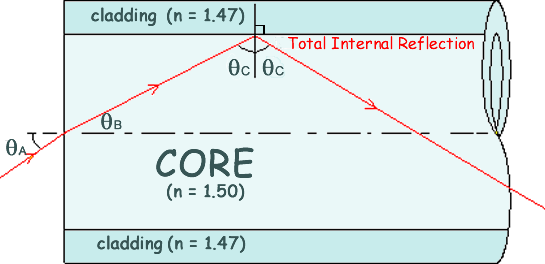

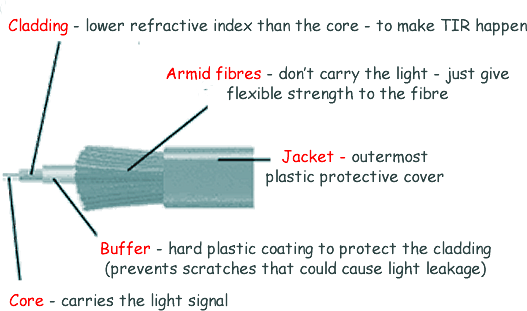

Fibre Optical Cable: Construction A fibre optic cable is made from a glass or plastic core, that carries the light, surrounded by a glass (or plastic) cladding of lower refractive index, which reflects “escaping” light back into the core. The fibres used in long-distance telecommunications are made of very pure glass rather than plastic, because glass does not absorb the enegy of the light signals as much as plastic does. For shorter distances, plastic is often used as it is cheaper. Without the cladding the light would pass between the fibres as they are all made of glass, would not have a lower refractive index boundary for TIR to occur at and therefore would allow light transfer. They are about usually about 120 micrometers in diameter - they are very thin strands.

Surface scratches can lead to 'light leakage' in a single fibre. Additional layers of treated paper, PVC or metal may further protect the outside of the fibre.

The overall cable construction is shown in the diagram below:

|

Follow me...

|