Uses of Fibre Optic Cables: Sensors

A Microbending

Sensor

A Microbending

Sensor

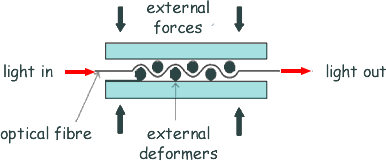

The microbend sensor was one of the earliest fiber optic sensors.

Microbend losses have always been a problem to the fiber optic cable designer, but it is this very same microbend loss effect in optical fibers which was exploited by the microbend sensor designer who adapted the microbend effect to the measurement of many physical parameters and physical variables such as temperature and pressure.

A microbending sensor

consists of two plates between which passes an optical fibre. The plates

have parallel grooves on their facing surfaces and the grooves from

the two plates interleave with each other.

The fibre passing between

the plates is therefore bent alternatively up and down.

When a fibre

is bent sufficiently the light in the core no longer meets the cladding

at an angle equal to or greater than the critical angle. Total Internal

Reflection therefore does not occur.

This is called microbending loss,

and the more a plate is bent, the more loss occurs.

This has a military

application of submarine detection.

Blood

Components Sensor

Blood

Components Sensor

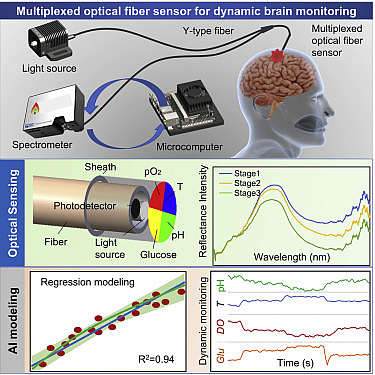

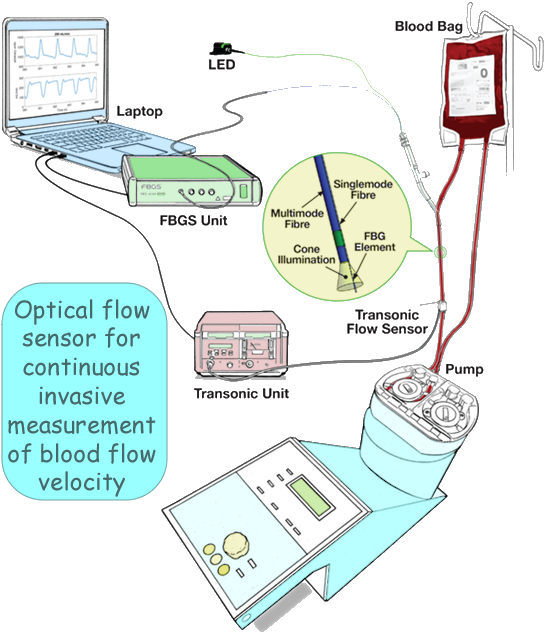

If we use the correct

wavelength we can measure the concentrations of specific components

of blood such as total protein, cholesterol, urea and uric acid quickly.

When the concentration is high, the output at the detector is less and

vice versa.

The concentrations of those chemicals are important to doctors

in the diagnosis and monitoring of certain disease conditions.

Fibre

optic sensors can give results very quickly without having to send samples

away to an analytical lab.

It is being adapted to many medical uses: