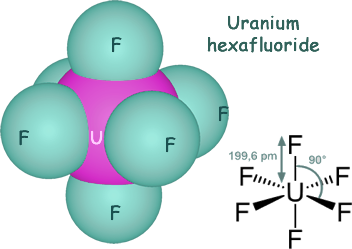

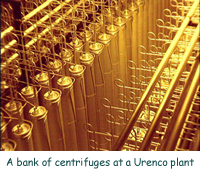

Nuclear Power - Uranium Enrichment Nuclear power plant fuel rods contain enriched Uranium, and nuclear weapons require highly enriched Uranium. Therefore Uranium enrichment is a highly sensitive, secretive technology. Historically, a number of enrichment processes have been demonstrated produced in the laboratory, but only two, the gaseous diffusion process and the centrifuge process, have operated on a commercial scale and only centrifugation is used today. One chemical process had been demonstrated to the pilot plant stage but in the end was not used commercially. The French Chemex process exploited a very slight difference in the two isotopes' propensity to change valency in oxidation/reduction, utilising aqueous (III valency) and organic (IV) phases.

|

Follow me...

|